Wood & Iron

iX Series

-

iX touch 2.0

Core Size M60 Weight 48±2g Backline Round / Rib -

iX SA 2.0

Core Size M60 Weight 45±2g Backline Round / Rib -

iXx 1.8

Core Size M60 Weight 48±2g Backline Round / Rib -

iXx 2.3

Core Size M60 Weight 50±2g Backline Round / Rib

Sticky Series

-

Sticky ULTRA LIGHT 1.0(27g)

Core Size M62 Weight 27±2g Backline Rib -

Sticky ULTRA LIGHT 1.0(34g)

Core Size M60 Weight 34±2g Backline Rib -

Sticky SUPER LIGHT 1.8

Core Size M60 Weight 35±2g Backline Round / Rib -

Sticky LIGHT 1.8

Core Size M60 Weight 43±2g Backline Round / Rib -

Sticky 1.8 Standard

Core Size M60 Weight 48±2g Backline Round / Rib -

Sticky 2.3 Standard

Core Size M60 Weight 50±2g Backline Round / Rib -

Sticky OVERSIZE 3.5

Core Size M60 Weight 50±2g Backline Round / Rib

Opus Grip Series

-

Sticky Opus 2 1.8

Core Size M60 Weight 48±2g Backline Round / Rib -

Sticky Opus 3 1.8

Core Size M60 Weight 48±2g Backline Round / Rib -

Sticky Opus 3 2.3

Core Size M60 Weight 50±2g Backline Round / Rib -

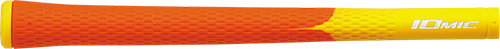

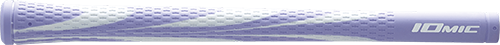

Sticky Opus Bi-color 1.8

Core Size M60 Weight 48±2g Backline Round / Rib -

Sticky Opus Black 1.8

Core Size M60 Weight 48±2g Backline Round / Rib -

X-Opus Black 2.3

Core Size M60 Weight 50±2g Backline Round / Rib

X-Grip Series

-

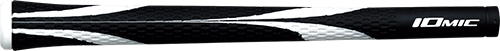

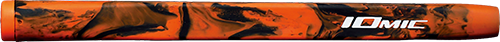

X-GRIP [type-DAIYA] 2.3

Core Size M60 Weight 50±2g Backline Round / Rib -

X-Evolution 2.6

Core Size M60 Weight 50±2g Backline Round / Rib

Art Grip Series

-

Sticky Black Army 1.8

Core Size M60 Weight 48±2g Backline Round / Rib -

Sticky Black Army 2.3

Core Size M60 Weight 50±2g Backline Round / Rib -

Sticky Army 1.8

Core Size M60 Weight 48±2g Backline Round / Rib

Black ARMOR 2 Series

-

Sticky Evolution 1.8

Core Size M60 Weight 48±2g Backline Round / Rib -

Sticky Evolution 2.3

Core Size M60 Weight 50±2g Backline Round / Rib -

X-Evolution 2.3

Core Size M60 Weight 50±2g Backline Round / Rib

LTC Grip Series

-

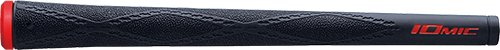

Moebius Black 1.8

Core Size M60 Weight 48±2g Backline Round

Order System

-

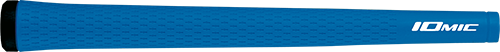

Sticky 1.8

Core Size M60・M62 Weight 48±2g Backline Round / Rib -

Sticky 2.3

Core Size M60 Weight 50±2g Backline Round / Rib -

X-GRIP [type-DAIYA] 2.3

Core Size M60 Weight 50±2g Backline Round / Rib

Big Size

-

StickyMID 4.4

Core Size M60 Weight 56±3g Backline Round -

Sticky JUMBO 5.5

Core Size M60 Weight 65±3g Backline Round

Lady's & Junior

-

Sticky Opus Lady’s

Core Size M56 Weight 40±2g Backline Rib -

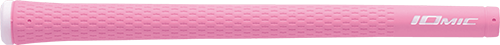

Sticky Lady's

Core Size M56 Weight 40±2g Backline Rib -

Sticky Army Lady's

Core Size M56 Weight 40±2g Backline Rib

mimic

-

mimic 1.5

Core Size M60 Weight 43±2g Backline Rib -

mimic Sticky Opus Bi-color 1.8

Core Size M60 Weight 48±2g Backline Round / Rib

Putter

-

Putter Grip 柔 -Ju-

Core Size M58 Weight 62±3g Grip Size MID -

I-Classic MID Putter

Core Size M58 Weight 72±3g Grip Size MID -

I-Classic Putter

Core Size M58 Weight 50±3g Grip Size Regular -

Black Army Putter

Core Size M58 Weight 65±3g Grip Size MID -

Army Putter

Core Size M58 Weight 65±3g Grip Size MID -

Putter Grip Regular/MID/Large

Core Size M58 Weight Regular/55±3g, MID/65±3g, Large/75±3g Grip Size Regular/MID/Large -

Opus2 Putter

Core Size M58 Weight 65±3g Grip Size MID -

Sticky Putter

Core Size M58 Weight 60±3g Grip Size MID -

Absolute-X

Core Size M58 Weight 65±3g Grip Size MID -

Absolute JUMBO Putter

Core Size M60 Weight 127±3g Grip Size Super Large

Distributors

-

AE SPORTS

MALAYSIA

Address KELAB DARUL EHSAN DRIVING RANGE, JALAN KERJA AIR LAMA, TAMAN TUN ABDUL RAZAK, AMPANG, SELANGOR 68000 Tel +60-3-4252-0406 (Office)

+60-19-682-8080 (Contact)Email cghindo@gmail.com -

GOLF SHAFTS ASIA

MALAYSIA

Address 12 JALAN PASAR, BANDAR TAMBUN, 31400 IPOH, PERAK Tel +60-5-546-5590 Email sales@golfshaftsasia.com Website https://golfshaftsasia.com -

GOLFSMART (M) SDN BHD

MALAYSIA

Address G-G-10, JALAN PJU 1A/3, ARA DAMANSARA, 47301 PETALING JAYA. Tel +603-74974950 Email wholesale@gsfgolf.com Website https://www.gsfgolf.com

-

VIN SPORTING HOUSE

MALAYSIA

Address NO.5, JALAN PENDIDIK U1/31, HICOM GLENMARIE INDUSTRIAL PARK 40150 SHAH ALAM, SELANGOR DARUL EHSAN Tel +603-5567-9800 Email golf@vinsportinghouse.com Website https://www.vinsportinghouse.com -

BFG Golf Pte Ltd

SINGAPORE

Address 31 Mandai Estate #01-01 Innovation Place Tower 4 Singapore 729933 Tel +65-9621 2282 Email lawrence@bfggolf.com -

VIN SPORTING HOUSE

SINGAPORE

Address 1, YISHUN INDUSTRIAL ST 1, #03-17. A'POSH BIZ HUB YISHUN 768160 Tel +65-67349698 Email golf@vinsportinghouse.com Website https://www.vinsportinghouse.com

-

ASIA GOLF

INDONESIA

Address JL. PINTU AIR 11 B C D E F JAKARTA 10710 Tel +62-21-3500-703 Email sales.golf@asiasmg.com Website https://asiagolf.id -

GolfshaftsandGrips

INDONESIA

Address Jl. Taman Pakubuwono VI no 10. Kebayoran Baru. Jakarta Selatan 12120. DKI Jakarta. Indonesia Tel +62 812-1213-9393 / +62 21 7392518 Email erwin.kosasih@alumni.usc.edu Website https://golfshaftsandgrips.com/ -

TOP GOLF

INDONESIA

Address THE BELLEZZA SHOPPING ARCADE G69-71 JI. ARTERI PERMATA HIJAU NO.34, JAKARTA SELATAN, 12210 Tel +62-21-5366-4820 Email sales@topgolfshopping.com Website https://topgolf.co.id/

-

Dynamic Sports Corporation

PHILIPPINES

Address 5th Floor K Plaza Building 18 Kamuning Road, Quezon City Philippines, 1105 Tel +632-89251578

+632-89252391Email info@dynamicsports.com.ph Website https://www.empiregolfshop.com/ -

PACSPORT

PHILIPPINES

Address 9/F ATHENAEUM BUILDING 160 LP LEVISTE ST, SALCEDO VILLAGE, MAKATI CITY 1227 Tel +632-8817-5872

+632-8812-6569Email ebgozo@pacsports.com Website http://www.pacsports.com -

EVOSPORTS GOLF LLP.

INDIA

Address 11th Floor, 4, SEA LORD, B-WING, GD SOMANI MARG, CUFFE PARADE, MUMBAI-400005, MAHARASHTRA, INDIA Tel +91-9850726867

+91-9321402045Email eosports.backoffice@gmail.com

info@evolutionsports.in

-

PIN HIGH

INDIA

Address SHOP NO.20, BASEMENT FLOOR, ANJANEYA COMPLEX 147, OLD AIRPORT ROAD, KODIHALLI, BANGALORE 560008 Tel +91-98804-88334 Email krishna@pinhigh.in Website https://pinhigh.in -

SUZUKOU VIET NAM CO.,LTD

VIET NAM

Address No 1, Alley 43, Dich Vong Hau Street, Dich Vong Hau Ward, Cau Giay District, Ha Noi City, VIETNAM Tel +84-916-288-889 Email jdmgolfvn@gmail.com Website https://www.jdmgolf.vn -

Dongguan Tangxia Yunling Sports Goods Trading Co., Ltd

CHINA

Address Room 318, Building 5, Jinxiu Huacui Apartment, Phase II, Guanlan Jinxiu Science Park, Longhua District, Shenzhen, China Tel +86-1355477-6820 Email lawrence@bfggolf.com

-

GSA GOLF Pty. Ltd.

AUSTRALIA

Address 8/347 BAY ROAD, CHELTENHAM, VICTORIA 3192 Tel +61-492-894-931 Email sales@golfshaftsaustralia.com Website https://golfshaftsaustralia.com -

GOLF ZERO

AUSTRALIA

Address SHOP 3/83 ASHMORE ROAD, BUNDALL 4217 QLD Tel +61-435-595-577 Email sho.golfzero@gmail.com Website http://www.golfzero-japan.com -

RETCO GOLF

AUSTRALIA

Address UNIT 4/7 ERETON DRIVE, ARUNDEL, 4214 Tel +61-7-5529-1196 Email trent@retcogolf.com.au Website www.retcogolf.com.au(NG)

-

Prosports International

UAE

Address AI Quoz Industrial Area, Dubai UAE Tel +971-4-3477737 Email sales@prosports.ae Website https://www.prosports.ae/ -

S2zerO PTY LTD

SOUTH AFRICA

Address 35 Linksfield Road, Dowerglen, Edenvale, South Africa Tel +27-83-937-4606 Email barend@s2zero.co.za Website https://www.s2zero.co.za

Address

- IOMIC (ASIA) Co., Ltd.

- Phothalai Golf Park, Room 105, 1st Floor, Building A, 28/2 Soi Rongrean Klonglumjeak, Klongchan Sub-district, Bangkapi District, Bangkok 10240, Thailand